Our Customer List

Ericsson

Akzonobel

J.P.Morgan

ABB

BASF

Bayer

Gemalto

3M

LG

KBC

Lyondell

GE

Magna

TD

PHILIPS

Akzonobel

J.P.Morgan

ABB

BASF

Bayer

Gemalto

3M

LG

KBC

Lyondell

GE

Magna

TD

PHILIPS

Examples Analaysis

The insured discovered multiple leaks in copper water pipes throughout the home .The insured recounted that he had had minor leaks in the copper water pipes over the previous 6 months, but none serious enough to submit a claim. Unfortunately, with no one home and no water alarm system, the basement filled with water during the vacation, causing a substantial loss. EXAMPLE NO.12

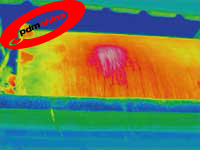

The insured discovered multiple leaks in copper water pipes throughout the home .The insured recounted that he had had minor leaks in the copper water pipes over the previous 6 months, but none serious enough to submit a claim. Unfortunately, with no one home and no water alarm system, the basement filled with water during the vacation, causing a substantial loss. EXAMPLE NO.12 Equipment failure and facility problems can cost you big money, even shut your company down. Now, through advanced technology in thermographic imagery and ground penetrating radar, you can fix equipment before it fails or predict the useful life of limited life components. EXAMPLE NO.9

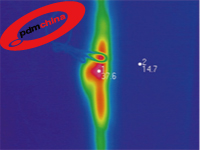

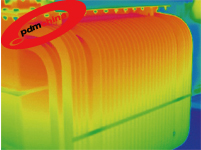

Equipment failure and facility problems can cost you big money, even shut your company down. Now, through advanced technology in thermographic imagery and ground penetrating radar, you can fix equipment before it fails or predict the useful life of limited life components. EXAMPLE NO.9 Preventative Maintenance is labor intensive, ineffective in identifying problems that develop between scheduled inspections, and therefore is not as cost-effective as Predictive Maintenance. On the other hand, since Predictive Maintenance inspections are performed while your equipment is in service. EXAMPLE NO.2

Preventative Maintenance is labor intensive, ineffective in identifying problems that develop between scheduled inspections, and therefore is not as cost-effective as Predictive Maintenance. On the other hand, since Predictive Maintenance inspections are performed while your equipment is in service. EXAMPLE NO.2 Thermal imaging is the only non-intrusive safe way to inspect for issues in both your electrical components and your mechancial equipment that you can't see with the naked eye.Thermographic inspections can detect loose or corroded connections, overloaded or unbalanced circuits, and can show where corrective action should be focused. EXAMPLE NO.1

Thermal imaging is the only non-intrusive safe way to inspect for issues in both your electrical components and your mechancial equipment that you can't see with the naked eye.Thermographic inspections can detect loose or corroded connections, overloaded or unbalanced circuits, and can show where corrective action should be focused. EXAMPLE NO.1