|

Electrical: Transformer Switchboard Capacitance |

|

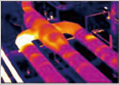

Mechanical: Motors Bearings Pump |

|

Process: Firebrick lining Relief valve Hearth |

|

Building: Building complex Envelope Leakage |

Potential failures are thermally detected and repaired during normal working

hours thus eliminating much of the overtime labor costs. The chances of a fault

occurring during premium time are about four times greater than in normal

working hours. There is clearly enormous potential for economy in this field by

detecting and repairing incipient fault conditions during normal working hours

under planned instead of emergency onditions.

Thermal Image |

Visible |

|

|

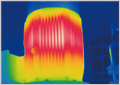

Thermal image shows the switchboard is running |

|

Advantage in electrical system :

SAVES MONEY

• Reduces unexpected failures

• Insurance Discounts

• Less expense for repairs

• Reduce costly unscheduled downtime or outages

SAVES TIME

• Easily identifies areas needing repair

• Reduces Emergency calls

INCREASES SAFETY

• Decreases risk of Fire

• Decreases Electrical and Mechanical catastrophic failure

MORE REASONS

• Extremely Reliable

• Identify problems immediately

• Follow analysis for future problems

For examples :

Pdmchina infrared Service is the most powerful electrical maintenance tool available. Our partners have provided Infrared Inspection services for many years. Infrared thermography is used to locate defects and potential failures in electrical equipment by identifying abnormal heating patterns that deviate from normal.

Electrical problems locate problems which allow the maintenance department to repair defects before catastrophic failure causing unscheduled power losses, equipment damage, or even personal injury or death. Infrared Inspections are extremely effective in locating problems on all electrical equipment.

Thermal Image |

Visible |

|

|

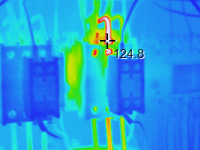

Thermal image shows the Connector is overheated |

|

On a small, medium voltage network severe fluctuations had led to complaints

over a period of six weeks. The high and medium voltage networks had been

subject to a detailed climbing inspection and many tests had been made to trace

the intermittent fault.

Infrared thermography was then deployed to assist in tracking down the trouble.

Within 20 minutes two hot joints were detected. When these were removed and

examined, severe corrosion and signs of internal arching was found but

externally no signs were evident that a problem existed.

Thermal Image |

Visible |

|

|

Thermal image shows the switchboard is running |

|