Infrared Inspection

|

Electrical: Transformer Switchboard Capacitance |

|

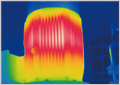

Mechanical: Motors Bearings Pump |

|

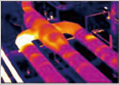

Process: Firebrick lining Relief valve Hearth |

|

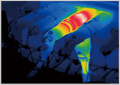

Building: Building complex Envelope Leakage |

Process Evaluation System

- Pumps, Inverters

- Fans,blowers,and fluidizers

- Conveyors Compressors

- Mixers and agitators

- Dust collectors

- Process rolls

- Gearboxes/reducers

- Control valves

- Seals and packing

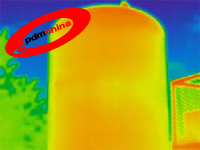

- Tank Levels

- Steam System

- Refractory Breakdown

- Sediment Buildup in tanks and process lines.

- Leaks, insulation degradation

Thermal Image |

Visible |

|

|

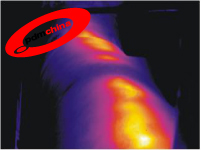

Thermal image shows the tank |

|

One insurance report indicates that within the chemical industry, 29% of catastrophic losses have been attributable to piping failures, with an average cost of $50 million per incident.

Thermal Image |

|

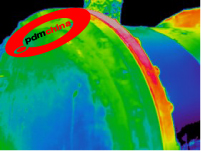

Thinning Pipe |

The concern today to conserve energy is not just in the cost of fuel which adds to the cost of the produced goods. It is as much about the environment and greenhouse gas emissions.

Thermal Image |

Visible |

|

|

Thermal image shows the Furnaces

|

|

Cool band spreading out from welded seam. Typical pattern indicating outside cool air being drawn into heater. This seam should be welded at first opportune time to prevent damage to the refractory lining. The heater efficiency is also being affected by adding cool air to be combustion gases.