|

Electrical: Transformer Switchboard Capacitance |

|

Mechanical: Motors Bearings Pump |

|

Process: Firebrick lining Relief valve Hearth |

|

Building: Building complex Envelope Leakage |

Infrared Thermography is one of the key technologies used to identify machine failure, complementary to such measures as performance checking using non-dimensional flow, measurement of pressure, vibration, and axial movement, lube-oil analysis etc. Bad lubrication is the main reason for abnormal uear of mechanical equipment. It is particular important to do the lubricated work of the equipment well under the environment of abominable job.

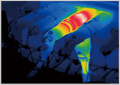

Thermal Image |

Visible |

|

|

Thermal image shows the bad lubrication |

|

Mechanical Applications :

• AC/DC Motors

• Pumps, Compressors, Fans, Hydraulics

• Drives/Conveyors, Pillow Blocks, Couplings, Gears, Pulleys, Shafts

• Shutoff Valves, Relief Valves

• Steam Systems- Steam Valves, Piping

• Turbines

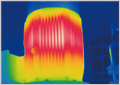

Thermal Image |

Visible |

|

|

Thermal image shows normal operation of motor |

|

The four main causes of Mechanical failure include:

• Bearing Failure

• High Ambient Temperature

• Overloading

• Misalignment.

ANYTIME AND FOR ANY CAUSE, A HIGHER-THAN-NORMAL WINDING TEMPERATURE IS CREATERED, MOTOR LIFE WILL BE REDUCED.

MOTOR WINDING INSULATIONS ARE PARTICULARLY TEMPERATURE-SENSITIVE.

A RULE-OF-THUMB SAYS FOR EVERY 10°C RISE IN TEMPERATURE, THE INSULATION LIFETIME IS REDUCED BY 50%.

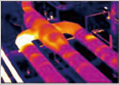

Thermal Image |

Visible |

|

|

Thermal image shows the internal defect of the motor |

|